Roofing Systems

Fully Adhered Roofing System

A fully adhered system, in its simplest form, means that the roof is being glued to the surface beneath it. The roofing membrane in a fully adhered system is usually held in place by employing the use of adhesives, hot asphalt or low rise foam. EPDM, TPO and PVC roof membranes can all be installed as fully adhered systems.

Benefits of Fully Adhered System

- Application on any slope

- Suitable for unusual roof configurations

- Lightweight system

- High wind uplift performance

- Aesthetics

- Perfectly suited for green roofs

The membrane is bonded to the insulation, which has been physically attached, utilizing mechanical fasteners, stress plates and/or adhesives. Either non-reinforced or scrim reinforced membrane can be used, with the non-reinforced membrane making up most adhered installations. Fully adhered systems are lightweight and ideal for a wide range of building sizes and geometric configurations, including contoured and high-slope roof applications.

Benefits of Fully Adhered System

The Main Benefits of Fully Adhered System

Aesthetically Pleasing

Fully adhered roof systems are an excellent choice for roof systems that are in view of the public eye. While other methods use fasteners or ballast to keep the roof system anchored, fully adhered roof systems use adhesive products which are hidden from view beneath the roof membrane’s surface. This allows the commercial roof to remain uniform in its overall appearance.

Lightweight and Flexible

Fully adhered systems are suitable for contoured roofs, roofs with irregular shape and any roof with limited load bearing capacity because they are lightweight and flexible. A fully adhered system can be used for a wide range of building sizes and geometric configurations, including high-slope applications and complex roofing projects.

High Wind Rating

Fully adhered roof systems also have a high wind uplift performance rating, which makes them a good choice for tall buildings or high-wind areas. Every square foot of membrane is bonded to the insulations in fully adhered roof systems, which means they have the least amount of membrane fluttering.

Time Tested and Proven

Fully adhered roofs first appeared in the 1960s and have become a time-proven method in the process of roof installation. Performance value, longevity, and long-term costs are all driving concerns for building architects and commercial construction professionals. Recent technological advances in application mean fully adhered roof systems are becoming the system of choice for many roof replacement applications across the country.

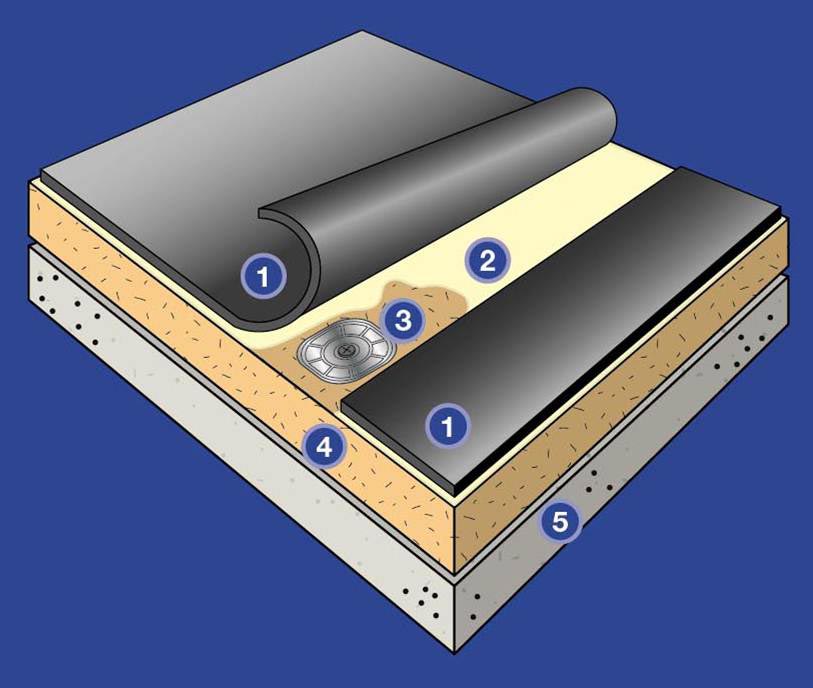

Fully Adhered (EPDM)

- EPDM membrane

- Contact Adhesive

- Fasteners and plates

- Acceptable Insulation

- Approved Roof Deck